Plastic injection molding is a manufacturing process that produces a wide range of plastic items. From simple bottle caps to complex automotive components, this approach provides flexibility, accuracy, and efficiency. Driven by Plastic Injection Molding In California state renowned for its creativity and strong manufacturing base has evolved into a centre for industry trendsetting and advancement.

The Method:

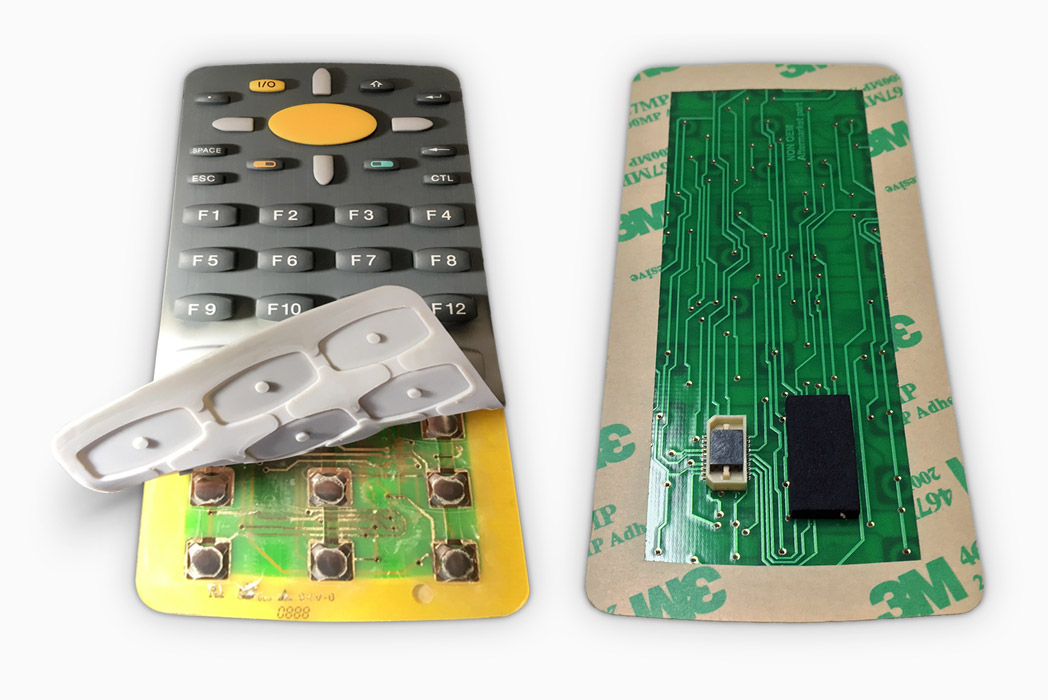

Plastic injection molding in California, is the process of filling a mold cavity with molten plastic. The plastic cools and solidifies into the intended form, then is removed from the mold. For mass production, this method is quite effective since it can produce thousands of exactly similar parts with minimal waste. This manufacturing method is even more flexible because it allows one to use a wide spectrum of plastics, from thermoplastics to thermosets.

The Evolution Of Plastic Injection Molding In California

Over the past ten years, Plastic Injection Molding In California sector has grown really significantly. The state is home to many businesses specializing in this field because of its large consumer market, availability of innovative technologies, and trained labour. Recent industry estimates project a compound annual growth rate (CAGR) of 5.6% for the California plastic injection molding market over the next five years. Demand in many other areas, including automotive, healthcare, electronics, and consumer goods, fuels this expansion.

Benefits :

Plastic injection molding boasts many benefits. The financial economy is one of the main advantages. For high-volume manufacturing, once the first mold is developed, the cost per part is really low, so this is a perfect choice. Furthermore, the procedure guarantees great consistency and accuracy, making sure every component satisfies exact criteria. For many businesses, plastic injection molding is also a popular technique since it allows for the creation of intricate forms with strict tolerances.

Environmental Issues And Innovations

Plastic Injection Molding In California business is likewise emphasising sustainability, given growing environmental issues. To lessen their environmental impact, businesses are funding biodegradable polymers, recycling initiatives, and energy-efficient equipment. Furthermore, becoming more common are innovations like 3D printing for mold construction and the use of recycled materials, thereby promoting environmental friendliness in the sector.

Difficulties And Prospectives:

The molding sector has difficulties, including changing raw material prices and the necessity of ongoing technological developments, notwithstanding its several benefits. These difficulties, too, offer chances. Businesses that can be creative and flexible enough to meet evolving consumer needs will flourish. California’s focus on technology and creativity helps it to lead the way in creating new materials and techniques capable of improving the sustainability and efficiency of plastic injection molding.

Your Realiale:

One of the best Leading plastic injection molding producer King Epoxy Emblem Co., Ltd. is renowned for its dedication to excellence and creativity. The business provides mold design, manufacturing, and finishing, among other services. They maintains its industry leadership by prioritising sustainability and ensuring customer satisfaction.